Decreasing Temporary Staff Turnover While Increasing Supervisor Production

Case Study

“John has helped us reduce team member turnover, increase fill rate, and minimize lead times to our customers. We have found his organization’s communication and engagement to be superior to anyone in their industry. From daily rosters to team member scheduling to quarterly recaps, John’s team has become an integral partner in our daily business.”

Corey R. – VP of Operations, Large Food Processing Plant in Lorain County Ohio

Case Study: Large Food Processing Plant in Lorain County Ohio

Our engagement with Customer began in June of 2017. Management told us to be successful we must decrease the turnover. They averaged over 800 new temporary workers in previous years, resulting in large lost time by their frontline supervisors.

They originally gave us 5 out of 49 employee slots. All 5 were on 2nd shift (their hardest to consistently keep filled). Our 4M Process is not stand-alone, it is part of our overall Hire-Correct Strategy we employ with every engagement. The bullet points below are an example of how we used our 4M Process to grow the account from 5 employees on 1 shift to 43 on 2 shifts, not including other various placements they granted us throughout the 8 months.

Monitor: We track and manage all of our employees. How can we promise you peak performance if we don’t know what our employees are doing?

- We checked in employees either digitally or in person daily.

- We examined “family/friend employee chains.” Evaluating on a case by case basis so we didn’t limit ourselves and still provided the best people possible.

Measure: We work with you to determine what you need from our employees in terms of production, performance and process. We then consistently quantify the 3 P’s and provide you reports on status and updates.

- We use a basic industrial math skill assessment that fit Customer model and did not offend potential employees.

- We notify the employees of their quota attainment. Understanding their production goals and what is expected of them is crucial for long term employment.

- We utilize a simple point system to determine worker’s reliability.

Modify: We met with them (daily, weekly, monthly, quarterly) to make adjustments to the project as needed. We call these Calibration Meetings. Calibrating and adjusting what we are doing to ensure top-end results.

- We distribute Customer specific Worker’s Guides to aid in productivity ramp up.

- As soon as we were alerted to it, We published the new incentive plan to the employees.

- Customer notified us when they had targeted an employee with potential to be a permanent hire before their 90 day anniversary. This was our opportunity to coach and motivate the employee appropriately for their potential next step.

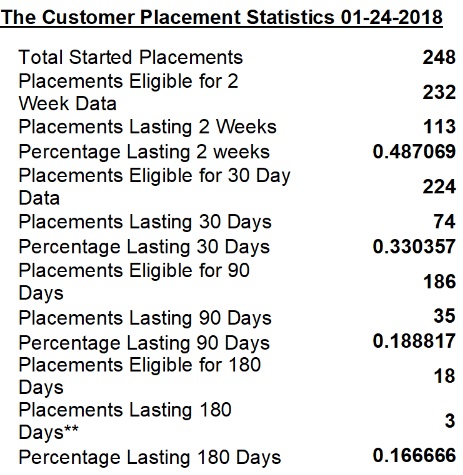

These first 3 steps of the 4M Process led to these results

Monetize: With adjustments made and implemented your organization will see increased production, reduced downtime and improvement to the overall work environment.

** 3 placements were hired on**

***One of those hired on was named the Rookie of the Year***

Summary Points

- More than doubled previous vendors’ 2-week data, on predominantly harder shift.

- 30-day retention rate higher than previous vendor 2-week data.

- We cut the number of temporary workers hired by over half per annum (320 with us while previous vendors were over 800) proportionately, freeing up frontline supervisors time over the last year.